IR4’s extensive experience enables us to provide benchmark Industrial Automation solutions to a range of industry sectors, providing solutions for industry wide challenges.

IR4 prides itself on the standardised systems it has developed for the mining sector, particularly earthmoving with the rebuilding of worn parts and extending the useful life of new parts. IR4 continues to grow its strong working relationships with many global leaders such as Caterpillar, Komatsu, Hitachi and Liebherr and is focused on delivering further solutions into this market.

IR4 prides itself on the standardised systems it has developed for the mining sector, particularly earthmoving with the rebuilding of worn parts and extending the useful life of new parts. IR4 continues to grow its strong working relationships with many global leaders such as Caterpillar, Komatsu, Hitachi and Liebherr and is focused on delivering further solutions into this market.

IR4’s systems demonstrate some of the best application of artificial intelligence in industrial automation, and our in-house IP offers real life solutions for our industry partners.

The team at IR4 have extensive experience and background in the construction industry particularly heavy fabrication solutions and the challenges they currently face. With labour shortages and associated obstacles, the desire for companies to adopt automation and overcome these challenges has never been greater. IR4 has successfully implemented multiple robots working at once in the construction industry and built state-of-the-art beamlines and material processing systems for the construction industry.

The team at IR4 have extensive experience and background in the construction industry particularly heavy fabrication solutions and the challenges they currently face. With labour shortages and associated obstacles, the desire for companies to adopt automation and overcome these challenges has never been greater. IR4 has successfully implemented multiple robots working at once in the construction industry and built state-of-the-art beamlines and material processing systems for the construction industry.

The team at IR4 have a passion for manufacturing sector and have many solutions we can offer this segment. Most of our experienced team has had first-hand experience in manufacturing and keen to assist with the challenges faced in the future. Delivering improvements in efficiency, productivity and quality while reducing labor costs and human error is our goal.

The team at IR4 have a passion for manufacturing sector and have many solutions we can offer this segment. Most of our experienced team has had first-hand experience in manufacturing and keen to assist with the challenges faced in the future. Delivering improvements in efficiency, productivity and quality while reducing labor costs and human error is our goal.

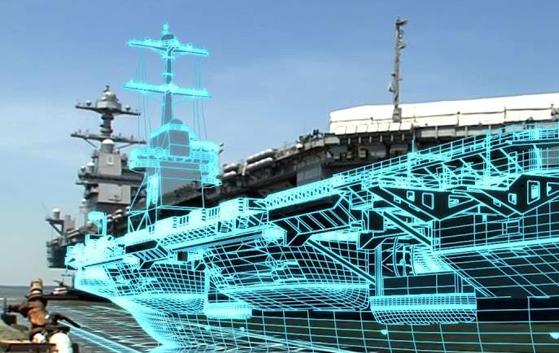

IR4 provides the shipbuilding industry specialised automation solutions to support and enhance shipbuilding processes. We understand the unique challenges and requirements of the shipbuilding sector and are able to offer tailored automation solutions for shipyards, vessel construction, and marine industry applications.

IR4 provides the shipbuilding industry specialised automation solutions to support and enhance shipbuilding processes. We understand the unique challenges and requirements of the shipbuilding sector and are able to offer tailored automation solutions for shipyards, vessel construction, and marine industry applications.

IR4 automation integration in building truck bodies and trailers involves the use of advanced technologies and automated processes to manufacture these heavy-duty vehicles. By leveraging IR4 advanced technologies and automated processes manufacturers can achieve higher levels of precision, consistency, and efficiency in the production of truck bodies.

IR4 automation integration in building truck bodies and trailers involves the use of advanced technologies and automated processes to manufacture these heavy-duty vehicles. By leveraging IR4 advanced technologies and automated processes manufacturers can achieve higher levels of precision, consistency, and efficiency in the production of truck bodies.

IR4 has many solutions that are suitable for the agriculture sector aimed at optimising efficiency, optimising resource utilisation and improve productivity. Our automated application for adding resistant wear for the agriculture GET’s is a good example. We also offer solutions for agriculture part manufacturing and processing.

IR4 has many solutions that are suitable for the agriculture sector aimed at optimising efficiency, optimising resource utilisation and improve productivity. Our automated application for adding resistant wear for the agriculture GET’s is a good example. We also offer solutions for agriculture part manufacturing and processing.

Our solutions are customized to meet your budgets, adhere to your timelines, achieve your goals, and most importantly, ultimately to help your business succeed and grow.

Our solutions are customized to meet your budgets, adhere to your timelines, achieve your goals, and most importantly, ultimately to help your business succeed and grow.